Search the Community

Showing results for tags 'watercooling'.

-

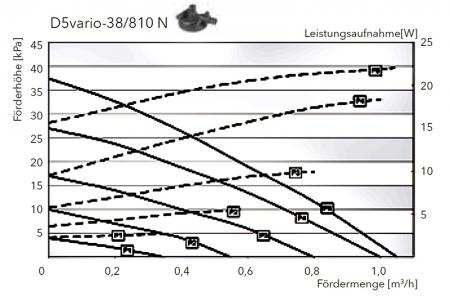

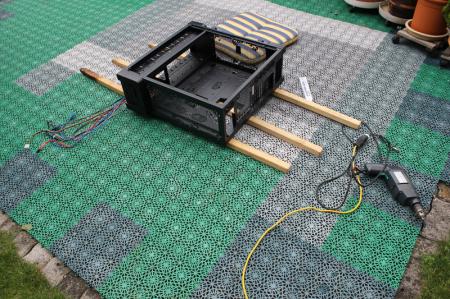

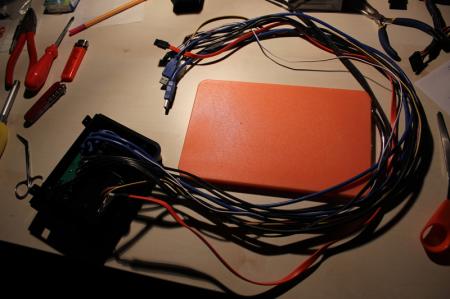

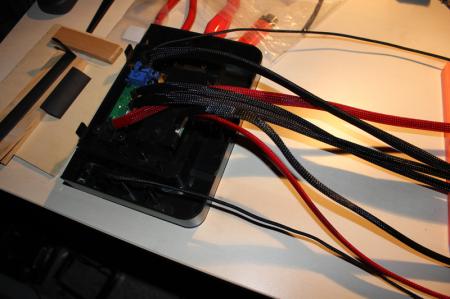

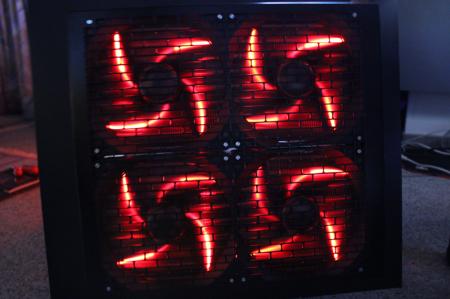

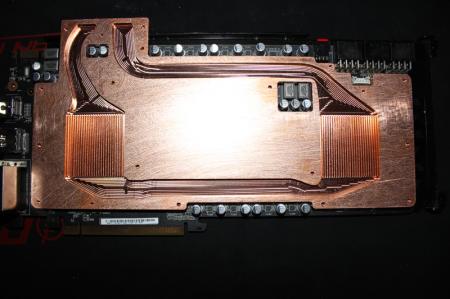

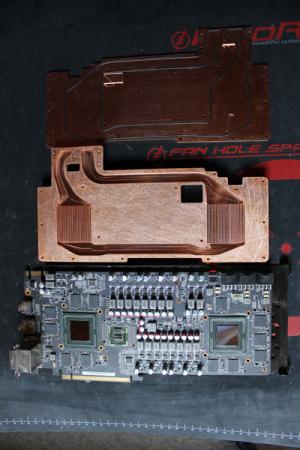

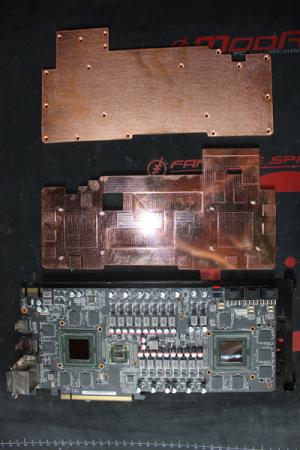

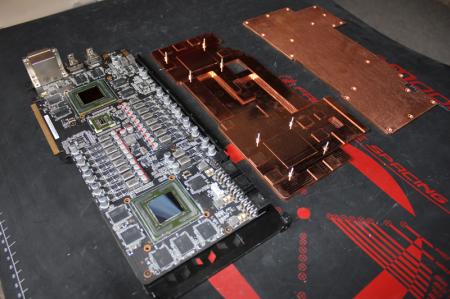

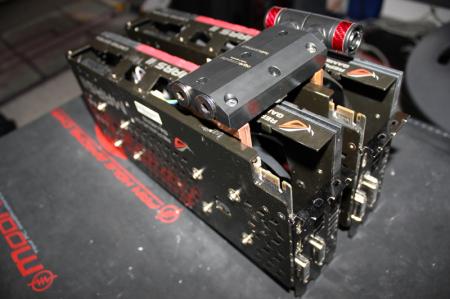

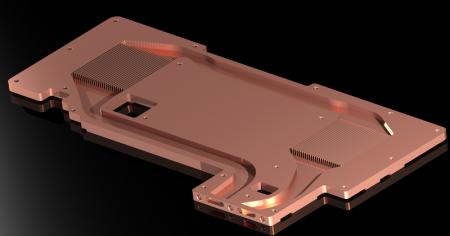

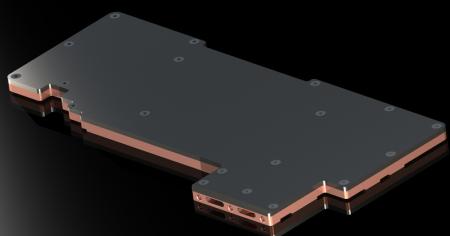

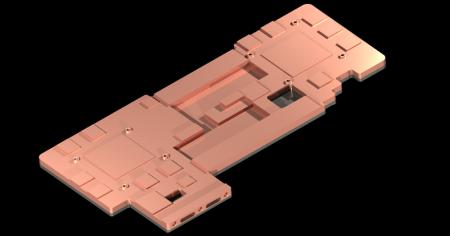

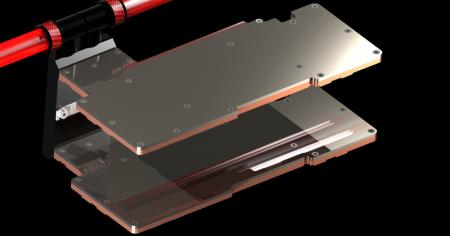

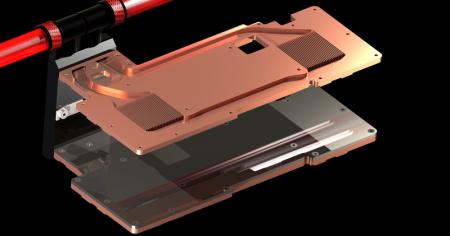

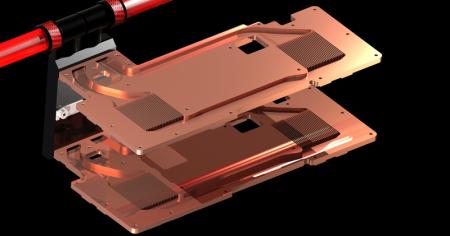

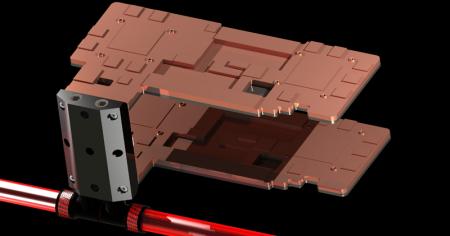

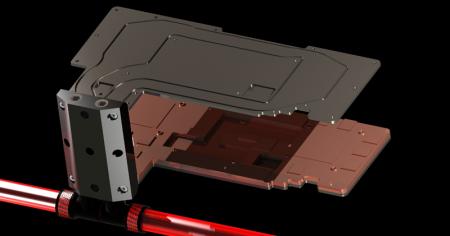

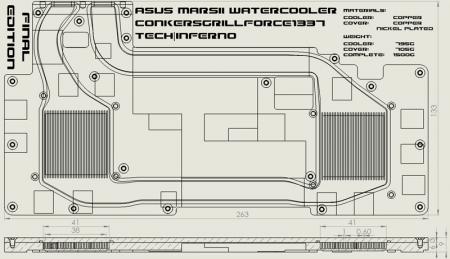

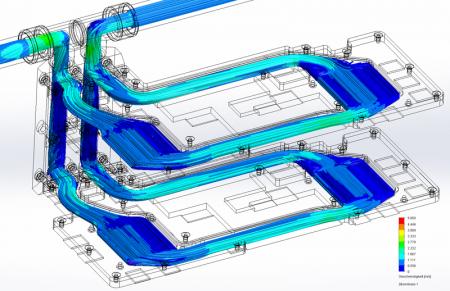

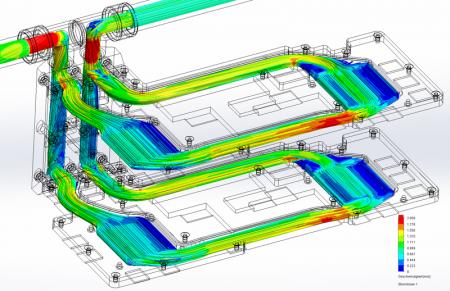

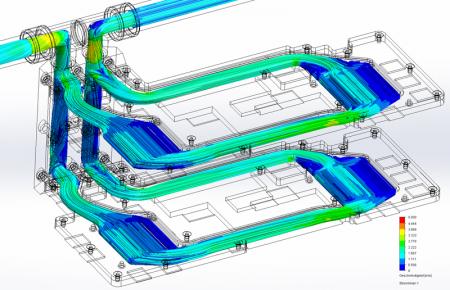

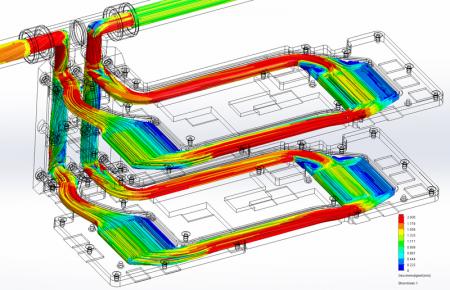

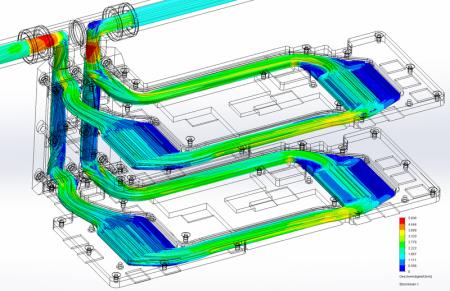

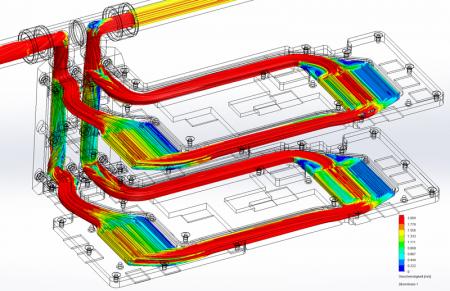

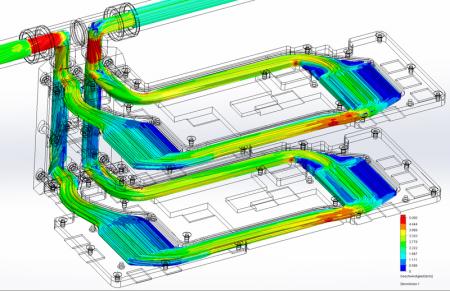

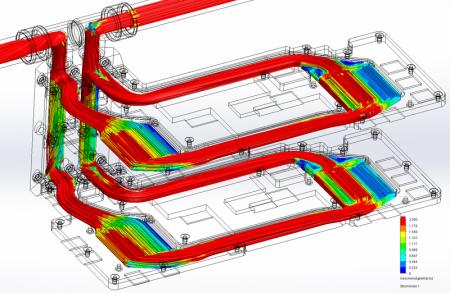

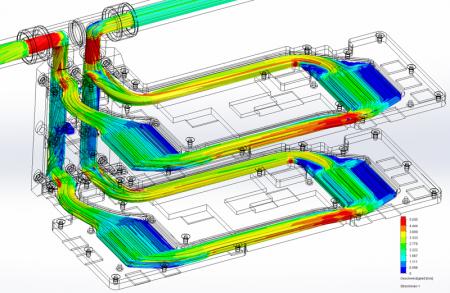

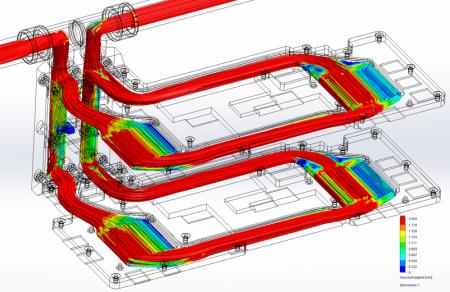

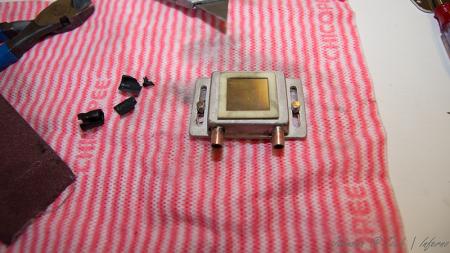

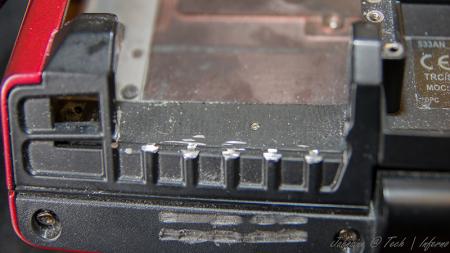

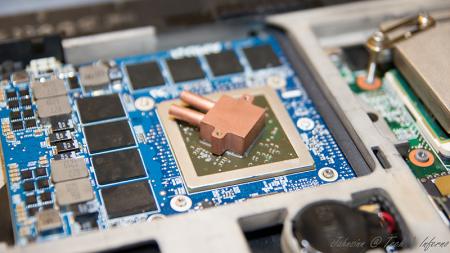

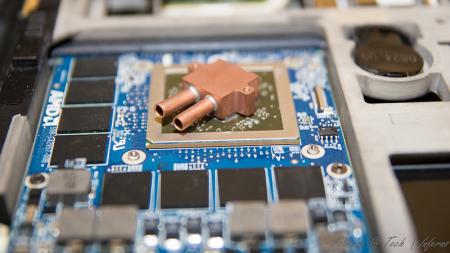

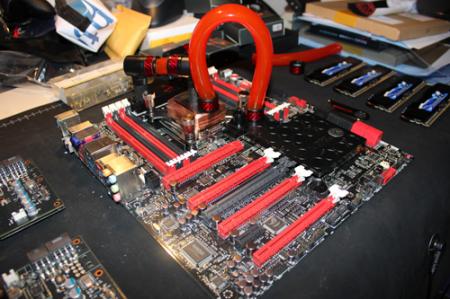

Asus MarsII QuadSLI Watercooled by ConkersGrillforce1337 Let's resurrect the graphic gods... Here it is, my next project, a self-designed watercooler especially for my Asus MarsII cards. Waterblock Design The existing heat sink of the Asus MarsII will be slightly modified so that the two watercoolers can be connected to the TwinConnect bridge respectively the circulation. The original look of the Asus MarsII is kept, because the design is awesome. As mentioned earlier, removing the IHSs of both GTX580s on each Asus MarsII has brought some benefits in terms of cooler design. I have been able to reduce the copper block of 1cm to 6mm, the thickness of the cover remains the same, because I want to hide the screws. The reduction of the height of the copper block makes itself felt especially in weight. Flow Simulations using Solidworks Flow Simulation 2013 (with 1000 flow lines) Stage 1: 1800RPM Stage 2: 2550RPM Stage 3: 3300RPM Stage 4: 4050RPM Stage 5: 4800RPM FullRes: Click here Hardware components Case: Xigmatek Elysium PSU: Enermax MaxRevo1500 + Corsair A850 Mainboard: Asus Rampage IV Extreme CPU: Intel Core i7-3960X RAM: 4x2Gb G.Skill RipjawsX 1866Mhz GPU: 2x Asus MarsII in QuadSLI Cooling components CPU: Corsair H100 RAM: Kingston HyperX Coolers GPU: self-designed watercooler Watercooling components Pump: Alphacool VPP655-T12 Reservoir: Phobya Balancer 250 Radiator: Watercool Mo-Ra3 360 PRO Tubing: Masterkleer 19/13mm Disassembly During the months of May and June, I got my Xigmatek Elysium case disassembled piece by piece. On one hand, it was necessary to clean the case completely after nearly two years of operation, on the other hand to get access to all the cables, which I wanted to sleeve. In addition, the mounting holes for the radiator and the reservoir had to be drilled. FullRes: Click here Sleeving + front door modding This I had never done before and it was a tedious piece of work. Two power supplies, various internal cables, pump cables, fan connectors,…everything should shine with red and black sleeving, respectively the 24pin ATX cables in red, black and silver sleeving . In addition, I removed the fan grill on the front door of the Xigmatek Elysium case and replaced it with clear plexiglass. FullRes: Click here Reassembly After the sleeving process was complete and everything was cleaned, I started the reassembly. At this time, the two MarsII waterblocks had not yet been delivered, so I installed my two GTX Titans to test the system and clean install Windows. FullRes: Click here Asus MarsII waterblocks A few days later it was time, the two water coolers were delivered. I made some checks and fortunately everything seemed to fit. In the production, there was a difference of 4/10mm in the direction of the inputs/ outlets, fortunately, this difference is not a problem provided. However, I noticed that one VRam-„isle“ was missing, I contacted Liquid-Extasy what went wrong, I have received no answer until now. This production error was also not a problem, as I still had excess 2mm pads from the rear Vrams. FullRes: Click here Looptest The time had come, the two GTX Titans were on temporary retirement. The first loop test I made with complete installation, the first test was pretty promising. Basically everything was tight after 8 hours of continuous operation of the loop except one of the two water blocks. The fact that one was dry, let me suggest that the second was not screwed on correctly. I made a second loop test with a rather unconventional installation, which was over 6 hours in operation. The result was convincing, no leaks. FullRes: Click here Let's resurrect the gods Now there was no holding back, the gods are not to rest on. I assembled both Asus MarsII cards, at the last check, I noticed that one graphics card had only partially contact between the 580 dies and the copper surface. I disassembled the card and used thermal pads instead of thermal compound as a temporary solution. I installed everything and after solving some BIOS error messages, I managed to get the system up and running. At idle, all four chips run at temperatures between 30-37 °C, that’s ok with a roomtemperature of 24°C. Under full load, the weakness of thermal pads makes massively noticeable, while the chips with MX-4 paste run at max 48°C, the chips with thermal pads heat up to 78°C. Btw, the entire system weighs 37,6kg. FullRes: Click here It's not over yet...thin copper plates are on the way to replace the thermal pads...

-

Hello, I am using on a MacBook Pro (Retina, 15-inch, Mid 2015) 2,2 GHz Intel Core i7 with Intel Iris Pro 1536 MB, Akitio TB2, a water-cooled Nvidia 1080 TI using the driver Nvidia Web Driver 378.05.05.15f01 OS: macOS Sierra v10.12.5 Script: automate-egpu.sh I would like to ask you : is there any chance to overclock it on macOS? Components: V-tubler Thermaltake C 1000 coolant 2x luna 12 red + led band Radiator EK Water Blocks EK-CoolStream SE 240 (Slim Dual) Pacific PT40-D5 Reservoir/Pump Combo 250 Akitio Thunder 2 pcie expansion Plexiglass, acrylic, plastic isolation, screws Water cooling fittings, pipes, hard tubing, without actually bending the tubing Lian Li PW-PCI-E38-1 Riser PCIe x16 3.0, 380mm, flexibil, High Speed, EMI Shielding + powered Openframe case Thermaltake Core P1 RM650 gold PSU+Paperclip Graphic card: Zotac water cooled 1080 TI Fe (Zotac 1080 TI FE + Separate mount of Titan X nickel waterblock)

- 2 replies

-

- overclock

- macbook pro

-

(and 2 more)

Tagged with:

-

Hello Tech Inferno eGPU community. Just doing some research and wanted to know how many people here implement watercooling into their eGPU rigs. Reply below if you do or you don't and why! If you do, what enclosure do you use? Regards, David

-

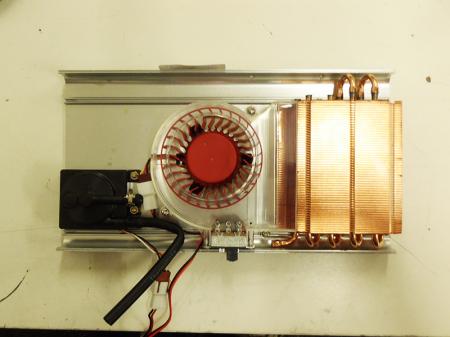

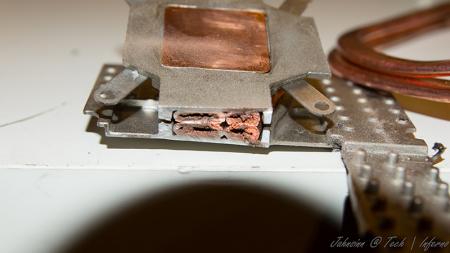

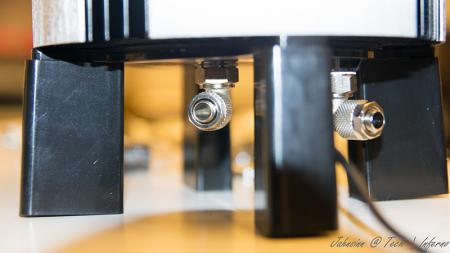

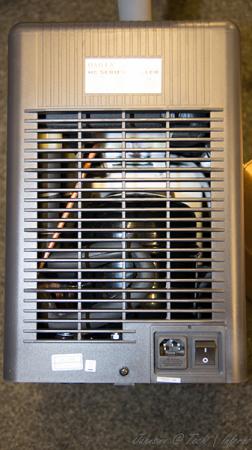

First of all, let me say I haven't finished yet. I'm still working on it and will update this thread from time to time due to much work at the moment. When I fitted my 940xm and the 7970m I got really mad of the heat and the fan noises even in idle mode. So I decided to get it all cooled with a silent, most important quiet, external water cooling system. I checked the internet and found evth I need to get it done. The most difficult thing was to find slim water blocks to cover the dies. I will list all the parts I used with article number and website if you're interested at the end of this post. First the overview. These parts are going to be used: Actually not much, so let's start. I start tubing at the inner hose socket of the reserator. This is the place where the pump is placed behind. You have to use a 10/8mm hose. By this, 10mm means the outside diameter of the hose, 8mm means the inside diameter. This is very important to know by everything you do on water cooling systems due to different fittings, barbs or reducers. Fit the hose and tighten it well with a spanner. Now you need a reducer to get on a 8/6mm hose. This is necessary to get in fitted to the chiller. At the other end you need to fit the 8/6mm hose. After this is done the 8/6mm hose leads into the chiller. A chiller pushs down your temps to a predefined value set by you, the minimum you can get theoretically is +3°C. Basically you can say it works like a refrigerator. This is very helpfully when you start gaming or other intense work on the laptop to keep the temps low. Here are some pics of it. To get the hose fitted the first custom made had to be done. Maybe I didn't know how it actually works, but I had no clue how else to do it without a modification... As you can see on the picture, the 1/4" adapter didn't fit to the chiller's nozzle. I really don't know what's the original idea by the developers. So the first adjustment had to be made. Cut the end of the nozzle as you can see on the pic. When this was done I noticed really pour casting quality inside the nozzle. This would massively reduce your flow speed. So I used a drill to get it out. Finally I got an outside diameter of 13mm at the nozzle. The adapter has 12mm inside diameter So just perfect to cut a M14 thread to both parts. Unfortunately I couldn't get closer due to the layout of the die. two washers solve this problem to get it proper tightened. To get it proper sealed I used teflon tape. Just the best way to get something sealed. Don't do it without any sealing! Use some Vaseline before you stick in the nozzles. Do the same with second side of course. At the end it'll look like that. Let's get to the CPU water block. I purchased the Thermaltake CL-W0052 Tide Water, originally made for desktop PCs to cool down the graphics card, on ebay to get all the stuff I'll need to do it. I chose that one because the water block has just a height of 8mm. Also all the hoses and clamps will be helpful. First drain the coolant. Then I opened the chassis and robbed all hoses and clamps. You'll need them in a couple of minutes. They're all bonded quite well, so just cut them at the ends. I also cut and removed the hoses of the water block itself, just to make sure everything is okay. I didn't want to get upset when I filled the system with water. So I cut them and removed the old adhesive. I then removed the original cpu heatsink and compared the die with the water block The water block as it was out from the box was just a touch too small to fit correctly onto the die. So I just removed the tape around the block. Now it was ready to get fitted. All I needed to do was loosing the existing bolts on the water block and tightened it with M2.5x20 hex nut bolts into the existing holes. At the end it looks like that. By the way, the mosfet heatsinks came with the tide water vga cooler. I also fitted the black hoses as they were, just without the glew and it still seals perfectly. To get the hoses guided out of the laptop you need to remove your fan control at the back of your laptop. When you're doing this, be careful not to touch the chassis as I did with whatever you use. I used the dremel and didn't see it for a while. What a shame! Nevermind, so let's get over to the gpu side. I bought a very tiny water block with just 15x15x7mm dimensions to not to exceed the height. So may be later I will be able to fit the backplate cover again. The water blocks would actually fit on the die, perfectly. But due to the layout of the gpu die the block just fits in diagonal postion. So useless for me. To get the water block in the right direction I unsoldered the copper plate of the original heatsink. That one has got the right dimensions to get this solved. Clean the copper plate from the old tin on top by using the Dremel or sandpaper. At the end that's the way it should work. Just to mention, also the holder came with Thermaltake tide water cooler. The bolts I bought seperatly on ebay. They are M1.6x20 but too long, so I cut them down to 15mm. Now they fit into the existing holes and push down the block properly Use now the -->small<-- black hoses robbed from Thermaltake chassis. These are the inside hoses, they're smaller. You need to use some adhesive because the clamps coming with the hoses are just a way too big and don't keep it tight to nozzle. Now just add some thermal paste between copper plate and die, and copper plate and water block. Tighten it all down. Finally it looks like that. [ATTACH=CONFIG]5105[/ATTACH] hoses leaded through the fan grill, gpu side. I mention again, just temporarily cause I'm still waiting for parts. in progress... [ATTACH=CONFIG]5107[/ATTACH] [ATTACH=CONFIG]5106[/ATTACH] cpu side [ATTACH=CONFIG]5108[/ATTACH][ATTACH=CONFIG]5109[/ATTACH] The hose laying is actually just in common sense. Nothing particular I should mention. Reserator -> 10/8mm hose -> 10/8mm to 8/6mm reducer -> 1/4" compression fitting -> 1/4" adapter for chiller -> chiller nozzle -> chiller -> nozzle, adapter, fitting -> 8/6mm hose -> Y-splitter first end hose -> 8/6mm hose -> quick coupling -> black hose (termaltake tide water) -> cpu block inlet-> cpu outlet -> black hose -> quick coupling -> 8/6mm -> Y-splitter second end hose -> 8/6mm hose -> 6mm barb -> small black hose (thermaltake tide water) -> gpu block inlet -> gpu outlet -> small black hose -> 6mm barb -> 8/6mm hose -> Y-splitter | Y-splitter -> 8/6mm hose -> 10/8 to 8/6mm reducer -> reserator update in progress...

- 25 replies

-

- 15

-

-

Posts like the one highlighted below are what make up the heart and soul of Tech|Inferno. We've got crazy users like HotPantsHenry that take a perfectly good working MSI GT60-0NC notebook with an 880m GPU and decide to go balls out by strapping on a waterblock to it using electrical tape..that's right electrical tape! Check out the rest of his thread here: https://forum.techinferno.com/index.php?/forums/topic/8923-msi-880m-overclock-help/ Original Post Content: Here is an awful picture, but will give you an idea of what is going on. Cpu cooling is stock. Even with minor OC to the cpu, the temps stay pretty cool. View full article

-

- watercooling

- msi

-

(and 1 more)

Tagged with:

-

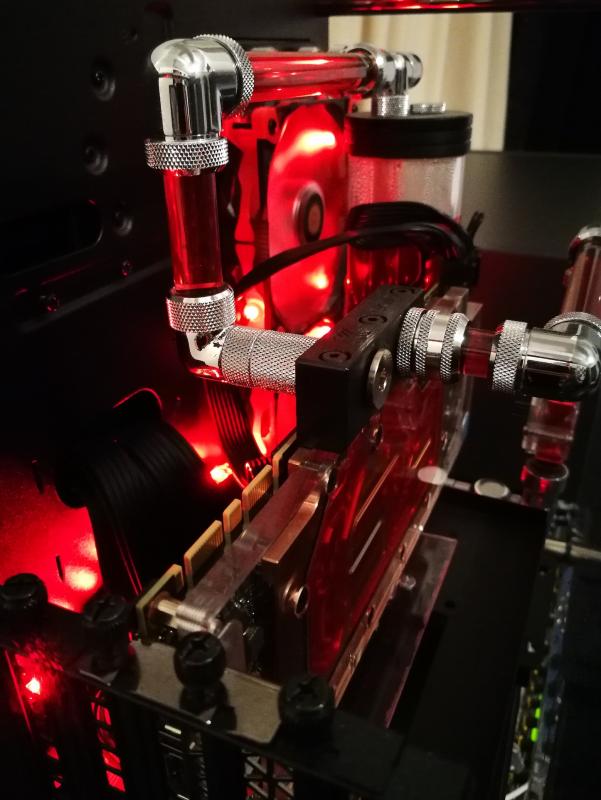

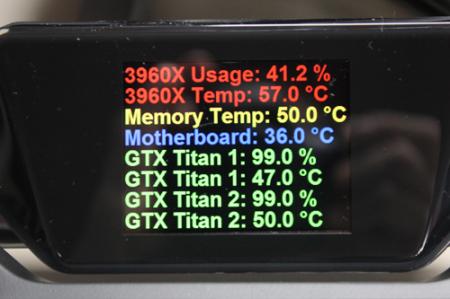

Xigmatek Elysium Full System Watercooling After my Asus MarsII watercooling project has “failed”, I went on with my two GTX Titans. I was long undecided whether I want to invest money again to set up or leave the system as it is with an unused radiator, reservoir and pump. In November I decided to create a list with all watercooling components which I would need to cool the entire system with one watercooling loop. Unfortunately not all parts were in stock at that time, especially the availability of the black 19/13 Monsoon Rotarys was unknown. I let the whole thing fall back a little, I had less time anyway and many things were going on. Now in January everything was in stock and I decided to order. My 25th birthday was coming, so I made myself a gift. Hardware: Case: Xigmatek Elysium PSU: Enermax MaxRevo1500 Mainboard: Asus Rampage IV Extreme CPU: Intel Core i7-3960X RAM: 4x8Gb G.Skill RipjawsZ 2133Mhz GPU: 2x Asus GTX Titan SLI Watercooling Parts: Pump: Alphacool VPP655-T12 Reservoir: Phobya Balancer 250 Radiator: Watercool Mo-Ra3 360 PRO Tubing: Masterkleer UV red 19/13mm Motherboard: EKWB RE4-Kit Acetal+Nickel CSQ CPU: Aquacomputer Cuplex Kryos HF GPU: Aquacomputer Kryographics nickelplated + Watercool backplate Everything arrived on January 10th, the only thing missing was the R4E motherboard cooling kit, which @svl7 ordered and paid as part of our PS4 deal. Thanks again. ;D On Friday the 17th everything was ready to install. As always, not everything went according to the plan, learning by doing and problem solving as usual. I removed the AX850 PSU and the H100 from the top of the case and also tried to clean the whole case a bit. After 5 hours everything was mounted in the Xigmatek Elysium case again and the system was ready for looptesting. My room looked as if a bomb had exploded. I did a looptest for almost 6 hours, checked the system afterwards and found no leak. I changed the pump to the Enermax 1500W PSU and started the machine. Temps were all good, I did a clean install of Windows 8.1 Pro, until late afternoon the system was ready for some testing. I changed back to my Logitech G19 to be able to monitor the system temps using HWinfo. (Thanks @Mumak for your amazing tool ;D). I overclocked my i7-3960X to 4.5Ghz and the two GTX Titans to 1155Mhz (core; memory stock), highest temperatures reached were 57°C for the CPU and 50°C for the GPUs with a room temperature of 19°C having the four 180mm radiator fans at minimum speed (~40% = ~300RPM) with full speed (700RPM) max temps are 5-10°C lower. FullRes: Click here Some work still needs to be done, I want to sleeve the second GPU powercable and the currently existing temporary solution has to be replaced with a proper installation. The list with parts I need is already prepared, I'll order in the next days...

-

So I started a watercooling project back in 2006-2007 and my goal was to build a system that looked great, was near silent and did a great job with cooling. After researching all the available blocks, reservoirs, radiators, tubes etc I decided to build a lian li based water cooling system with custom imported parts from aquacomputers that included the reservoir and fan grill. I also used danger den blocks (maze I believe) for the GPU/CPU and a bix2 radiator with dual 120mm fans. The setup worked amazingly well, it was quiet and the temperatures were always 30c and below with overvolting + overclocking. I no longer have this particular system (got lost when I moved to medical school) but it still brings back fond memories and I plan to build another one when ivy bridge is released. Link to gallery: http://forum.techinferno.com/members/brian-k--albums4.htm

- 1 reply

-

- aquacomputer

- bix2

-

(and 3 more)

Tagged with: