Innovation Cooling

Registered User-

Posts

23 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Downloads

Everything posted by Innovation Cooling

-

Just back from vacation & currently battening down for a little tropical squall this weekend Lost my home PC due to lightening strike(s) So a couple days reconfiguring all and should be back to work on the info you guys are generating. Should have some more contact images in the next week or so Plus we are still looking for volunteers/guinea pigs for CP testing

-

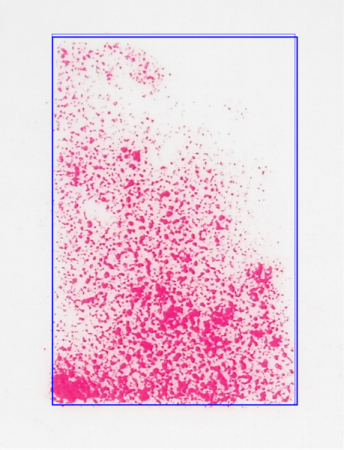

Test is straight forward - take one "A" and one "B" - shiny sides to the IHS and sink so the frosted sides are facing each other. Mount your sink as you normally would - WITHOUT ANY COMPOUND - Try to make a clean print and not move under pressure Dismount and remove paper - blank throw away - Red/pink image is your print that you send back You can scan or photograph image and post for discussion while waiting for results. label key envelope with your name or some identifier and forum so we can link thermals to CP Sensor Products has a "key" somewhere on their site that will give you a general interpretation of of your pressure +/- 10% - I will see if I can locate it and post it up.

-

Terrific! = send me your address at [email protected] with CP in the subject line

-

Lots of good info obtained. Raw images reveal much as well as pictures of paste impressions I cannot find the exact full die size but then have not looked too hard yet but initially pressure is very good as I suspected it would be and contact appears to be around 50% - 60%, 9/10 th's of a centimeter So basically you have half the area for dissipating 35W - +2X the thermal stress on a compound in an environment that is already warmer than most to begin with, little wonder why people are experiencing accelerated compound degradation. I currently have 3 people on tap for C/P testing it would be nice to get a broader profile of 20 to 30 and to see how things trend.

-

I am doing a reliability study and looking for people to do a simple Contact & Pressure (C/P) test to link to their recorded temperatures - two pieces of plastic paper mount sink as you would normally would release and remove throw away blank then mail back self addressed envelope for lab analysis. Lots of good info % contact area, psi are key and can be linked to long term reliability as quoted below. Laptops are about the toughest thermal environment out there and this would be useful data to have N I was taking a look at some published information on laptop reliability linked below and a rough analysis might be with their 30% failure rate in 3years approx 1/3 of that due to breakage and about 2/3 or 20% of all laptops is a component failure probably due in large part to high thermal loads - Heat is number one enemy of electronics. After a re-paste on a PC in the overclockers forums you have an average of 61C after a repaste and the laptops so far average 71 C after a re-paste. I think the extra 10C is the dividing line, in the PC market you may see a few degrees decline and here and there you get the rare 15 -20 C degree improvement but generally most of those are mount related issues unless the compound has been installed a couple of years or more. The PC failures were generally less than half laptops. The prevalence of early temperature creep in laptops is quite surprising along with the relatively large number of 85 - 90 C systems reported---- 25 to 30 C higher than the PC's, if you have a weak component those kinds of temps have a good chance of killing it. As a kind of general recommendation to avoid being the 1 in 5 failures and as a good maintenance procedure has been suggested here blowing the dust out regularly, I would add a secondary laptop cooler as well as changing the compound every-time it creeps up 10 C past the initial install temps. The cooler it is and the longer time periods it remains cool, the odds that longer system life increases. http://www.squaretrade.com/htm/pdf/S...ility_1109.pdf http://cache.gawker.com/assets/image...uaretrade3.jpg Gartner Says Annual Failure Rates of PCs Are Improving, but Manufacturers Can Do Better

-

Some background Paste impressions: Poor mounting pressure good mounting pressure & good contact - difference between mounts -6 C - light glaze indicates good pressure. Another example - Contact paper sample with paste impression of the same mount Light glaze on center indicates good contact and pressure in that area Another example

-

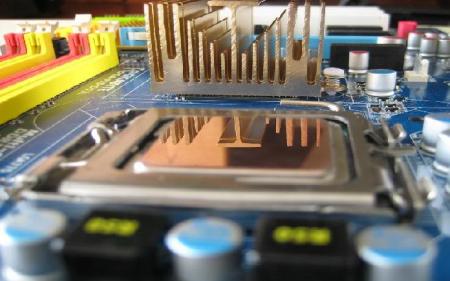

<meta http-equiv="CONTENT-TYPE" content="text/html; charset=utf-8"> Here is some general application info for desktop PC's for a 30mm X 30mm IHS - for rectangular type installations that vary from this you can just ratio the amount up or down to the new area Application Notes -Amount of Applied Compound - FAQ * * There is always some debate on amount of applied compound to use, our approach is based on a best to worst case scenario with a one size fits all so the user can experience best odds of a successful mount out of the gate without having to redo his mount. * * Say that Intel has a spec of Flat and parallel // to .002. - At the extreme end you get something like the 2 images of the candidate below, to fill that gap/volume you need .05 ml volume of compound for a 30mm X 30mm area about the size of a grain of rice. * * Our difference with the rice method comes from the other side of the equation The heat sink base, while many HS bases are good some can be off as much as the IHS and to cover the contingency of irregular contour on both sink & IHS and as few people lap to correct the problem (5%?)and fewer lap to perfection so we add another .05 ml for a total of 0.1ml. * Another factor associated with irregular contours is another mil or two layer of compound is added on the high spots depending on the pressure applied. To fill that gap we add another .05 ml for a total recommended amount of 0.15 ml which approx. equals our 5-5.5mm size bead on center. IF YOU ARE NOT SURE PEEL BACK THE LABEL TO SEE ML REGISTRATION MARKS AND USE 0.15-2ml EXCESS JUST SQUISHES OUT - I HAVE MEASURED THIS WITH A MICROMETER @ 50 PSI AND AT ROOM TEMP YOU REACH 95% OF THE BOND-LINE THICKNESS (BLT) IN TWO HOURS 99% OR MAYBE 1/2 DEGREE OVERNIGHT AFTER THE INITIAL 2 HOURS * Thermal compound is a volume application to fill gaps, not one of weight, liquid spread-ability etc. and our opinion is that whatever the compound you still need the equivalent volume to close that gap. * * Additionally it is important to apply enough compound, because as the paste thins it spreads it reaches a maximum zone where air is reformed into the paste application between the sink and his leading to decreased performance and early compound failure. This effect is well-documented and known as Laplacian Growth AKA cusp formation and viscous fingering. Fast Simulation of Laplacian Growth YouTube - Broadcast Yourself Laplacian Growth in thermal compounds Laplacian Growth - a good visual explanation http://www.physics.ubc.ca/pitp/archives/theory/2004talks/wiegmann.pdf Application

-

I am aware of everyone of them, I have saved/ recorded them and even know the physical location they originated from..... Here is one from overclock.net CPU IHS scratched, is this normal? - Overclock.net - Overclocking.net The scratches shown here are claimed to be IC Diamond. It is physically impossible for ICD to have caused those scratches either the top to bottom sanded grain most likely from lapping or the random scratches. Any abrasives expert would testify the scratches could only have been produced from particle sizes 10X the size as what makes up ICD. Bottom picture is the result of concentrated lapping with ICD no large grain scratching in sight, go figure. There are no "large" diamond chips in the compound we buy from one of the largest and most reputable US manufacturers, if you understand the process it is just not possible - it is like saying you have silver nuggets coming out of your tube of AS5. Unfortunately a couple of hardware reviewers commented on it without much thought overlooking the fact that in the test series alone they did 25 mounts without mention of how many mounts were run in previous testing series which could have been 50? 100? 200? all on a micron thick laser etch? Basically it is a non issue, urban/internet myth, negative buzz marketing etc. Just to note aluminum oxide which is a component in most TIM's is nearly as hard as diamond and will even cut glass and stone, just because diamond is the hardest does not mean there are not close competitors. Some interesting reading out there if you are into that stuff is what different cutting materials are used to cut copper, iron, plastic etc. each has it it's own +/- 's and good to know what to use next time you drill a hole. I have seen 90 PSI on a bare die in a server. Smaller contact area pressure its going to go up, most are probably well over 50lbs. Been trying to get get some Contact/pressure images on another notebook giveaway but no takers as of yet.

-

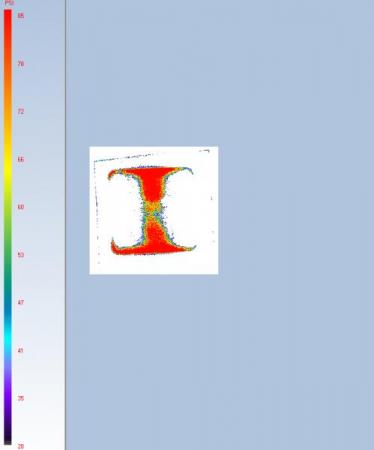

FAQ Thermal Reliability OEM's Spec material bulk loadings above a 90+ % for reliability. IC Diamond has a 94% bulk loading which includes 92% diamond + miscellaneous material. There are different kinds of thermal resistance. One is contact resistance which the retail compounds mostly rely on by being of higher liquid content so they flow well into the voids and air gaps and with great or low contact resistance which enhances thermal performance so that end users are satisfied with the performance and enjoy instant gratification. The Problem with Thin, Liquid, Low Viscosity Thermal Compounds Low viscosity, highly liquid thermal pastes enjoy an initial success with low contact resistance but this also make them susceptible to Pump Out. Pump Out occurs when the system heats up, the joint compresses, and a little of the liquid is pushed out. After a sufficient number of cycles, the paste has shrunken in size leaving voids and causing a contact resistance failure. A variant of compound failure, Bake Out , occurs when consistently high thermal stress causes thermal degradation of the liquid. Pump Out and Bake Out reflect the research of many in the thermal community and hundreds of technical papers exist on this well-documented issue. Illustration 1: Innovation Cooling has an ongoing program of reliability testing. Pictured below are some initial accelerated tests with some 3X10 glass slides,. Attached picture of test result was run for 20 hours at 150C, the center picture ICD is IC Diamond. The others are commonly used retail performance pastes, this highlights the stability of ICD7. The competition compounds feature the formation of voids, and span the range of initial failure to complete failure. IC diamond was observed to have no visible points of failure under these conditions. The picture is back lighted so the void formation is clearly visible Liquid is a necessary component where thermal pastes are concerned otherwise you would be applying a powder. IC Diamond uses much less liquid so consequently is much less prone to failures as the liquid is wicked or baked away The shrinkage of the compound is almost non existent due to the low liquid volume content to begin with and so maintains contact/ thermal performance for extended periods and by design to set up into a crayon like consistency over time, still pliable and relying on the high bulk Diamond conductivity for performance as you are left with basically diamond held coherently together with the polymeric binders and is easily removed when re-liquefied with a solvent So in short the reason it is thick is that it is harder to pump a solid than a liquid and provides a basis for long term extended reliability. High viscosity or thickness of compound is a positive feature to seek out and necessary for for long term reliability It's easy to design a compound for performance and it is also easy to design for reliability It is very hard to do both in one package

-

From the public data taken so far an average of -1.23 C out of 14 tests in IC Diamond's favor definitely one of the more competitive compounds, however the sample size is small generally you do not see a stabilization of the numbers till you hit around 30+ test samples. At around 30-40 tests you get a 95% confidence on the data and does not change much after that as in the AS5 chart below the average has changed only a couple of tenths of a degree C either way from the initial 34 tests to 200 end user tests. I do have some Corsair H70 stock compound tests to add from OCUK which is supposed to be Shin Etsu but I am not sure whether it is the better or lessor of the two Shin Etsu's I am familiar with, If the better then the average will go to -2 C from the 1.23 C which is what I would expect from my numbers but my numbers don't count. The other factor for notebooks in particular is longevity of the compound to consider - I am running a longevity study on another notebook forum and I have a few people @ 1,5 to 2 years with no change in temperature while other repasted laptops with other retail compounds are experiencing initial failure after 4 or 5 months. your call see next post on reliability

-

FAQ on the scratch issue Some background on the subject - 100 years of standard Industry practice on abrasives is well documented and well understood by those in the business. Most thermal compounds are liquid sandpaper or lapping compounds by definition. Light gray compounds are usually/mostly made up of aluminum oxide. (Check MSDS for AS5,Ceramique, ShinEtsu, Dow etc. hard metal oxides are more common than you would think in thermal compounds) Aluminum oxide is what they make sandpaper out of.....MOHS Hardness scale 9 Diamond on the MOHS hardness scale: 10 Copper MOHS: 3 To be abrasive you just have to be harder than the material to be cut. Most thermal compounds have particle sizes in the range of 600 - 800 same as your 600 - 800 sandpaper http://www.unc.edu/~rowlett/units/scales/grit.html If you are ambitious, you can calculate cutting speeds and material removal between diamond -- the hardest, (cubic boron nitride is actually harder than diamond) and the second hardest -- aluminum oxide. For the insignificant distance traveled, equivalent pressures, You will not see any difference between the two under normal use. Abrasives have to move to work. For all compounds- if you are a hardware reviewer who re-installs his sink 50 times a week or constantly rotates the sink under pressure they are going to see wear regardless of the compound used then should switch to something less abrasive if they have an issue with it like a zinc oxide compound. Empirically I have run 20+ of these giveaway's with over 800 user tests at this point and has not been an issue. In 3 years I have had no emails, phone calls or any contact whatsoever or complaints on the subject I would like to note that IC Diamond is classified/called a Flour in the business, below is an image of a IHS intentionally lapped with ICD - This can be accomplished with just about any thermal compound. Another way to picture it - Most thermal compounds are approximately 600- 800 grit, so take some typical aluminum oxide 600 grit sand paper and Mount it between sink and IHS Generally 80% of all retail sinks have 50+ PSI contact pressure, if you have high spots with an irregular contour the high spots can have a PSI of 100 lbs (see picture) now rotate the sink back and forth a few times under pressure it's going to leave a polished mark, so a general caution for any thermal compound but not ICD in particular. Also note we are doing a video comparing an assortment of compounds and their polishing capability along with microscopic images of the results with enough detail to qualify as a professional analysis and alleviate any concerns people may have.

-

Innovation Cooling (IC ) will giveaway 100 syringes of IC Diamond 24 thermal compound to Tech | Inferno forum members who have registered as a forum member techinferno prior to June 26 2011 and wish to participate in our survey ALL POTENTIAL PARTICIPANTS MUST POST THEIR INTENT TO PARTICIPATE IN THIS THREAD IN ORDER TO RECEIVE THEIR FREE TIM. PLEASE BE SURE TO BENCHMARK YOUR CPU TEMPS WITH YOUR CURRENT TIM AND RECORD YOUR RESULTS BEFORE USING ICD24 FOR TESTING. WE NEED BEFORE AND AFTER PLEASE (Ambient, idle, load at the very least)! Instructions and Qualifiers 1.) 1 Syringe per responding forum member. 2.) This is a on a first come basis. I will post notice on this forum when the giveaway ends 3.) Participating members are to post your test results on this forum within the first 30 days after receiving the sample. Gentleman's agreement.(THOSE WHO DO NOT HONOR THE AGREEMENT WILL BE FOREVER IMMORTALIZED ON THE WALL OF SHAME WHICH WILL BE POSTED AT THE COMPLETION OF THE SURVEY) 4.) Email me your mailing address in a format we can cut and paste easily for processing. 5.) Must agree to test the product and give feedback to the forum, and thus to Innovation Cooling (Current load/idle/ambient temps + fan speed then load/idle/ambient temps + fan speed with IC24) The specifics will be posted in a separate Results Thread, we will be looking for simple data feedback, before and after results as well as longer term reliability data and looking forward to actual comparisons in application methods and comparing products from other manufacturers. We would like to first get CPU, GPU's, , and Laptops results as a priority, then any you are free to apply/experiment on other components with remaining balance. Desktop test dara is also acceptable All personal information is kept entirely confidential and destroyed upon completion of giveaway. Please PM me if you have any questions. Thanks everyone and I look forward to working with you all and hopefully learning something in the process. Again to register for your survey sample post IN THIS THREAD "ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST AND POST MY RESULTS" After you have posted your registration Email to complete registration. We are mailing from the USA so allow time for any international processing and shipping . MAKE SURE YOUR OWN ADDRESS IS CORRECT - WE JUST CUT AND PASTE - IF IT IS NOT DELIVERED DUE TO REGISTRANT'S ERRORS WE DO NOT RE-MAIL SAMPLES EMAIL ADDRESS FOR REGISTRATION -- [email protected] All the best Andrew President Innovation Cooling *EDIT by StamatisX* Post your results here: http://forum.techinferno.com/general-notebook-discussions/913-ic-diamond-24-survey-results.html